This report is the 2016 annual report on government information disclosure compiled by the Beijing Intellectual Property Office in accordance with the requirements of the Regulations on Government Information Disclosure in People’s Republic of China (PRC) (hereinafter referred to as the Regulations).

The full text includes an overview, including the situation of voluntary disclosure of government information, the situation of disclosure and non-disclosure of government information according to the application, the personnel, fees and exemptions of government information disclosure, the consultation of government information disclosure, the application for administrative reconsideration and administrative litigation due to government information disclosure, the main problems, improvements and other matters that need to be reported.

The electronic version of this report can be downloaded from the government website of Beijing Intellectual Property Office (http://zscqj.beijing.gov.cn). If you have any questions about this report, please contact: Beijing Intellectual Property Office, tel: 84080089 84080086.

I. Overview

According to the requirements of the Regulations, our bureau has set up a leading group and working group for government information disclosure, which is responsible for promoting, guiding, coordinating and supervising the government information disclosure of our bureau, set up a special information application acceptance point, and opened a column on the website of our bureau for government information disclosure, focusing on the government information voluntarily disclosed by our bureau; Open a web page according to the application, further smooth the channels for accepting information disclosure, and facilitate the masses to apply for information disclosure. By the end of 2016, the government information disclosure work of our bureau was running smoothly, and the consultation, application and reply of government information disclosure were progressing smoothly.

Following the establishment of a leading group for the disclosure of government information, and the publication of the government information disclosure guide and annual report, our bureau set up a confidentiality review institution of this department in early October 2014, and formulated a document on the confidentiality review mechanism, namely "Beijing Intellectual Property Office Information Disclosure Confidentiality Review System". In 2015, our bureau has established relevant working mechanisms such as information monitoring and false information clarification, and formulated the Administrative Measures for Government Information of Beijing Intellectual Property Office and the System for Clarification of False or Incomplete Information. At the same time, the organization responsible for information monitoring and clarification of false information has been clarified and set up in the office, which will clarify false information through the Internet, radio, television, newspapers, press conferences and other channels and release accurate government information.

In the whole year, five special trainings were organized to strengthen the government information disclosure work, and nearly 260 staff members from bureaus and institutions participated. At the same time, actively improve the government website platform and optimize the information disclosure channels. Our bureau further adjusted and improved the various functional sections of the portal website, and effectively cleaned up the empty links and dead columns. On this basis, do a good job of web application page and test the online application function. The column layout of government information disclosure tends to be more humanized and rationalized, the page display function is simple and beautiful, and the column classification is fresher, which greatly improves the user experience level.

II. Voluntary disclosure of government information

In accordance with the scope of voluntary disclosure of government information stipulated in Articles 9 to 12 of the Regulations, our bureau has carried out the work of cleaning up and cataloguing government information, and in accordance with Article 15 of the Regulations, we have made voluntary disclosure of government information through government websites, newspapers, urban management broadcasts, press conferences, communication and dialogue sessions, and forums for soliciting opinions. In accordance with the provisions of Article 16 of the Regulations, a request point for government information disclosure has been established to facilitate citizens, legal persons or other organizations to obtain government information.

(1) Disclosure of information

In 2016, our bureau voluntarily disclosed 553 pieces of government information through the column of government information disclosure, of which the full-text electronic rate reached 100%.

Among the information voluntarily disclosed, there are 135 official government information (notices, announcements, etc.), accounting for 22.6% of the total; There are 416 pieces of business dynamic information, including departmental work dynamics and results publicity, accounting for 77.4% of the total.

In 2016, our bureau released the dynamic information of intellectual property protection in the city in time, released the information of intellectual property and patent work closely related to the obligee, scientific research institutes, enterprises and institutions and the public, interpreted the latest policies and measures, and clarified the social problems related to intellectual property in time, which played a positive role in promoting the creation, application, protection and management of intellectual property in our city.

(2) Open form

In order to facilitate the public to understand the information, our bureau has carried out various forms of government information disclosure through government websites, government information disclosure columns, newspapers, radio, WeChat WeChat official account and other media. The government website of our bureau publishes government information in time by using words and pictures, and opens a column of "Government Information Disclosure" to cooperate with the implementation of the Regulations. Regularly hold the "City-wide Intellectual Property Work Conference" and "Beijing Intellectual Property Press Conference" to release authoritative intellectual property statistics and maintain communication between Chinese and foreign media; Use "4.26" Intellectual Property Day and China Patent Week to organize publicity activities, widely publicize the intellectual property policies and regulations of our city to the public, answer questions for the public, and create a social atmosphere of respecting knowledge and encouraging innovation.

Iii. disclosure of government information according to application

In 2016, our bureau accepted 3 items disclosed according to the application by letter, replied to the applicant within the prescribed time limit, and issued a notice that the government information did not exist. In the disclosure work according to the application, our bureau paid attention to strengthening communication with the applicants, doing a good job in explanation and reply, answering nearly 500 telephone calls and on-site consultations, and there were no complaints and reconsideration lawsuits arising from the disclosure of government information.

IV. Personnel and Income and Expenditure

(1) Information of staff

There are 7 part-time staff engaged in government information disclosure in our bureau.

(two) according to the application for disclosure of government information charges

In 2016, there was no charge for the disclosure of government information according to the application.

(three) according to the application for disclosure of government information fee waiver.

In 2016, there was no charge reduction or exemption for the disclosure of government information according to the application.

(4) Expenses related to litigation.

In 2016, there was no litigation-related expenses in our bureau.

V. Consultation situation

In 2016, the bureau received nearly 417 consultations from citizens, legal persons and other organizations on government information disclosure.

VI. Administrative reconsideration and administrative litigation

In 2016, there were no administrative reconsideration and administrative litigation cases due to the disclosure of government information.

VII. Implementation of Key Points of Government Information Disclosure in 2016

(1) Implementation of information disclosure in key areas

1, to promote the operation of administrative power information disclosure.

Further increase the information disclosure of administrative organs’ administrative examination and approval, administrative licensing and administrative punishment, and actively promote the open and transparent operation of administrative power. The first is to promote the disclosure of administrative examination and approval information. Open the list of administrative examination and approval items of our bureau, open the power operation process according to law, and accept social supervision. Strengthen the disclosure of information on the adjustment of administrative examination and approval items, and timely disclose the information on the administrative examination and approval items that have been cancelled, decentralized, cleaned up and implemented by the authorities around the decision-making and deployment of decentralization in the State Council. Continue to promote the information disclosure of administrative licensing, and strengthen the information disclosure of basis, conditions, procedures, quantity, time limit, catalogue of materials to be submitted and handling situation. In accordance with the requirements of relevant documents, our bureau timely released the service guide through the government website platform on matters such as patent agency audit, patent licensing contract filing, patent grant declaration, etc., to guide applicants to apply for and understand the progress of service. At the same time, the Beijing local standard DB11/T 1182—2015 "Specification for Grade Evaluation of Patent Agencies" (hereinafter referred to as "Specification") was formulated and published, which strengthened the management of patent agency industry and standardized the practice behavior of patent agents and patent agencies.

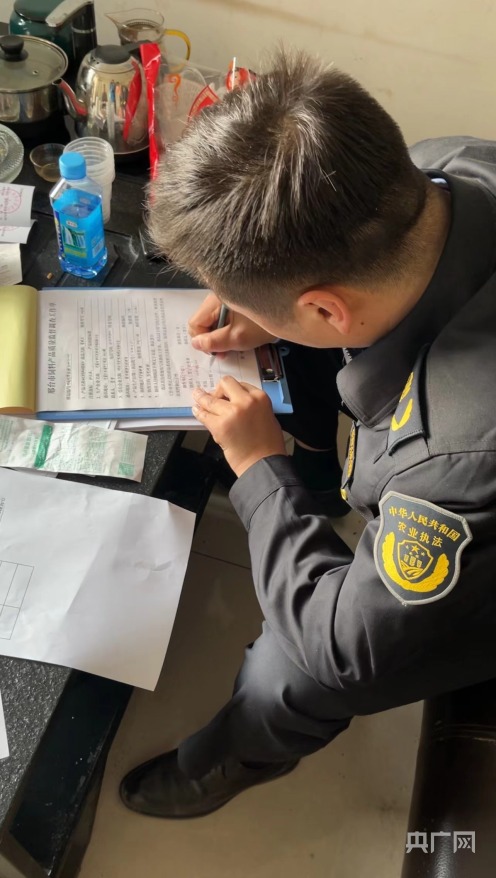

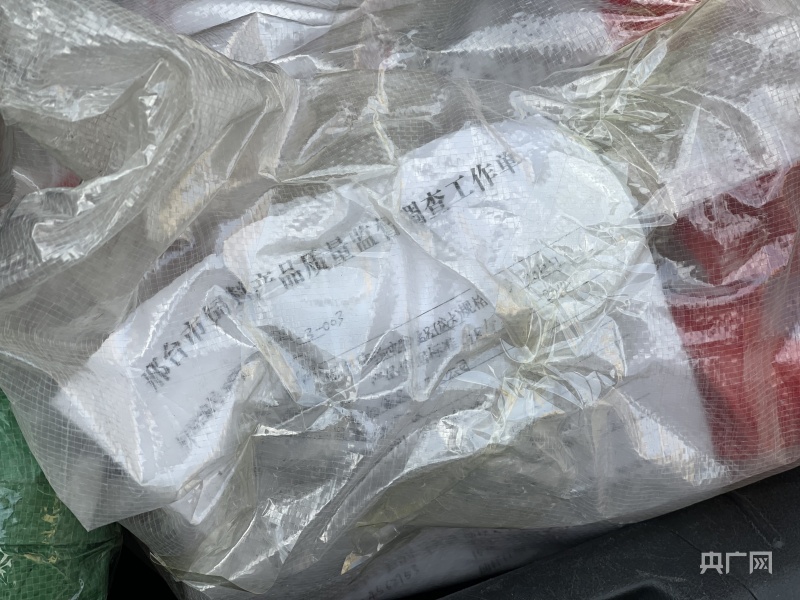

The second is to promote the disclosure of administrative punishment information. Our bureau has actively implemented the requirements of China National Intellectual Property Administration’s Notice on Disclosure of Information about Patent Administrative Law Enforcement Cases and the Notice of the Municipal "Doubles" Office on Issues Related to Doing a Good Job of Information Separation in Combating Infringement and Counterfeiting Administrative Punishment Cases in Our City, intensified the information disclosure of manufacturing and selling counterfeit and shoddy goods and administrative punishment cases infringing intellectual property rights, and formulated a work plan for information disclosure of patent administrative cases of Beijing Intellectual Property Office. The administrative punishment matters were made public according to law, and the name of the administrative case, the name of the punished person, the main illegal facts, the types, basis and results of punishment were made public on their own initiative, and social concerns were promptly responded. At present, the case of handling patent infringement disputes in Beijing in 2015 (January-December) has been released.

2, continue to promote the budget and the "three public" funds disclosure.

Increase the publicity of fiscal funds and improve the transparency of public funds. In accordance with the unified requirements of the whole city, our bureau earnestly implements the financial budget and final accounts and the disclosure of the "three public" funds, and constantly refines the contents of the budget and final accounts and the "three public" funds. In March, the "Department Budget of Beijing Intellectual Property Office in 2016" was published on the government website; In August, the "final accounts of Beijing Intellectual Property Office in 2015, three public funds and administrative funds" were made public.

3. Strengthen the disclosure of public resource allocation information.

In strict accordance with the relevant regulations of Beijing Municipality on government procurement management in 2016, the government procurement project budget, procurement process, procurement results, detailed public bidding announcement, bid winning announcement, bid bidding announcement and other changes and procurement information will be disclosed on the government website platform in a timely manner for major projects of organs and subordinate units.

4. Strengthen the disclosure of public service information.

Build a public information service platform for intellectual property rights in Beijing, search patents quickly and conveniently, and inquire about practical information such as patent technology transfer and transaction demand.

(2) Policy interpretation.

Strengthen the interpretation of policy information, enhance public understanding, respond to social concerns in a timely manner, and play a positive guiding role. In 2016, the General Office of the Beijing Municipal People’s Government forwarded the Development Plan of Intellectual Property (Patent) in Beijing during the Thirteenth Five-Year Plan period, and issued the Opinions of the Beijing Municipal Government on Accelerating the Construction of a Zone with the Best Intellectual Property Rights, putting forward new goals for the development of intellectual property in the capital in light of the new situation, strengthening the deployment of special projects, and clarifying safeguard measures. Through the interpretation of documents published by the government website platform and Beijing Daily, our bureau makes in-depth and detailed analysis to the public. According to the requirements of "Several Provisions of Beijing Municipality on Standardizing the Discretion of Administrative Punishment", our bureau formulated the "Provisions of Beijing Intellectual Property Office on the Discretion of Administrative Punishment (Trial)", which clearly explained the punishment for counterfeiting patents and the organizers’ failure to perform their duties during the exhibition, and the reasons for exercising the discretion. According to the provisions of the Measures for the Administration of Patent Grants in Beijing, we have studied and formulated the Detailed Rules for the Implementation of the Measures for the Administration of Patent Grants in Beijing (for Trial Implementation) to further standardize the patent grant work in our city.

In 2016, the Bureau also issued a number of documents, such as the Implementation Opinions on Accelerating the Development of Intellectual Property Services in the Capital, and the Promotion Plan for the Development Plan of Intellectual Property Services in the Capital in 2016. Before the policy document was issued, it carried out in-depth research and argumentation and solicited opinions. After the policy was issued, it released a large number of supporting information on the background and significance of the policy document through various channels such as press conferences, government websites, public hotlines and Weibo WeChat platforms, which enabled the media and the public to interpret it. The main person in charge and spokesperson of our bureau also actively participated in it. After the press conference and major conference activities, they were interviewed and reported by the media to deeply interpret the hot issues and relevant policies of public concern.

(III) Construction of institutional mechanisms

Following the establishment of a leading group for government information disclosure, and the publication of the government information disclosure guide and annual report, the department’s confidentiality review institution was set up in the office of the Security Committee of the Beijing Intellectual Property Office, with 23 people, consisting of bureau leaders and heads of various offices, and a document on the confidentiality review mechanism, The Confidentiality Review System for Information Disclosure of the Beijing Intellectual Property Office, was also formulated.

In 2016, the Bureau established and improved relevant working mechanisms such as information monitoring and false information clarification, and formulated the Administrative Measures for Government Information of Beijing Intellectual Property Office and the System for Clarification of False or Incomplete Information. At the same time, the organization responsible for information monitoring and clarification of false information was established in the office, consisting of six staff members. It will clarify false information through the Internet, radio, television, newspapers, press conferences and other channels, and release accurate government information.

(four) each unit to guide the local area, the system to do a good job in public work.

In order to further improve the disclosure of government information, our bureau issued the Beijing Municipal Government Information Disclosure Regulations to all business offices, institutions and district and county intellectual property offices, and held a forum to interpret the Beijing Municipal Government Information Disclosure Regulations in detail in combination with practical work. The office staff within the business scope of administrative examination and approval, licensing and punishment have a deep understanding of the importance of government information disclosure.

Eight, the main problems and improvement measures

In 2016, the government information disclosure work of our bureau has been steadily promoted, and some achievements have been made, but there are still some problems: First, it is necessary to further strengthen business training, improve the professional quality of government affairs disclosure staff, and make government affairs disclosure work better serve the society, industry and the public; Second, the content of information disclosure needs to be further enriched and improved. Government information disclosure is a policy-oriented and legal work involving people’s production, life and scientific research activities. Although our bureau has established various working systems, we should deepen our understanding and application of the Regulations in specific operations, constantly strengthen the research on difficult issues in this system and this industry, improve the overall level of government information disclosure in our bureau, form a supervision mechanism of administration and handling affairs according to law, and promote the healthy development of intellectual property in our city.

Beijing Intellectual Property Office

March 2017